The VerteX : It’s all about control.

The latest addition to the industry-standard RPM family, VerteX takes a great concept and drives it to its ultimate conclusion. The VerteX system is designed to deliver industry-leading accuracy, repeatability and too-to-tool matching. It brings the PL measurement process under control so that your epitaxial process stays firmly under control.

What’s New About VerteX?

Like all PL tools, VerteX measures photoluminescence wavelength and intensity. But the VerteX design goes to great lengths to eliminate all sources of variation in the measurement. Not only that, VerteX is designed to eliminate the sources of variation between tools – so that you can run your wafers through multiple PL tools and have total confidence that the results will match.

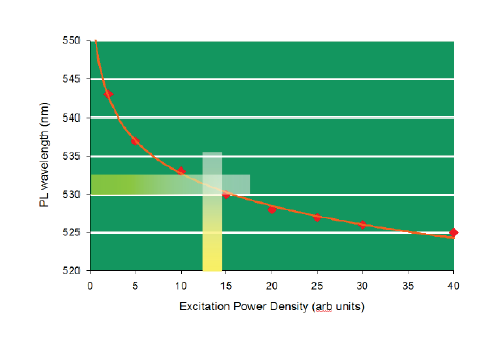

As an example, consider one source of variation – the excitation power density. The PL emission from many epitaxial structures depends strongly on the excitation conditions. Using a novel, on-board beam profiler, VerteX constantly monitors both the laser power AND the focal spot dimensions so you always know the power density. That means you can adjust the power density to a particular value and VerteX will maintain that value as the laser power varies. And there’s more. In production facilities with multiple VerteX tools, you can dial in the entire tool set to have identical excitation conditions. We call this Adaptive Power Density Control.

VerteX Versatility

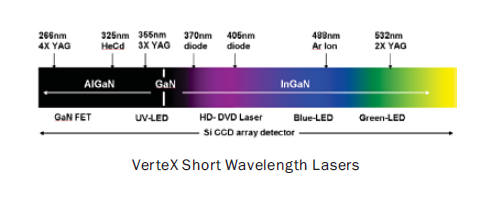

VerteX is designed to provide accurate, precise and repeatable PL metrology across the entire wavelength range. This includes high-Al content AlGaN alloys for GaN FET’s and UV lasers to the Antimonides out in the MIR and everything in between. VerteX offers a catalogue of more than 15 standard lasers and the ability to fiber-feed a virtually unlimited array of sources.

The monochromator can be fitted with up to three gratings and two array detectors — and, once configured, every optical component is selected under computer control. To ensure the highest possible wavelength accuracy, VerteX contains its own built-in spectral source for monochromator calibration.

VerteX can accommodate up to 4 internally mounted lasers. Two of those laser feature a continuously-variable power control with feedback loop.

Wherever possible, we have standardized on direct delivery of the laser beam. However, large lasers can be fiber connected.

For film thickness measurements, the system can be fitted with a white light source. The VerteX software now includes a Fourier Transform facility for data interpretation.

VerteX Automation

For high-volume applications, VerteX is easily upgradeable to robotic wafer handling. Robot handling reduces operator interaction to less than one hour per shift, enhances throughput efficiency and reduces wafer handling damage.

VerteX Lasers

VerteX can accommodate an even wider range of built-in, direct delivery lasers. Wherever possible, it avoids the complications of fiber launching. In the short wavelength region,the system can now provide a Q-Switch laser at 355nm, diode lasers at 375nm and 405nm and DPSS lasers at 440 and 560 nm. The advantages are obvious — For example, by using a 375 or 405 nm diode laser, problems associated with cap thickness variations in GaN LED wafers can be eliminated.

All VerteX lasers are factory aligned on kinematical mounts. This greatly simplifies the need for time consuming and critical alignment. The kinematic mounting system has a further benefit — it is easy to add new lasers with different form factors or emission wavelengths, allowing VerteX to be tailored to provide the ideal excitation conditions for a particular application.

VerteX and Green LEDs

It is well known that the emission wavelength of Green InGaN LED’s is then strongly dependent on forward current or, in the case of PL, on excitation power density. PL to EL matching is difficult and small changes in excitation conditions can lead to large variations in PL.

VerteX lets you select the excitation power that is most appropriate for your materials–giving accurate PL to EL matching and providing faster feedback to enable run-to-run control and correction of growth parameters.

VerteX Software

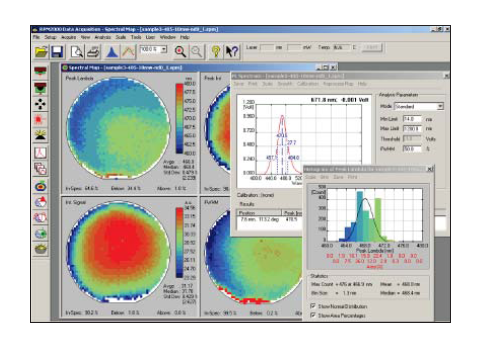

With nearly 300 RPM systems in the field, Nanometrics understands exactly what users expect from a PL mapping tool. Years of customer feedback have resulted in a comprehensive and robust software package and interface. Based on the highly proven RPM software, the VerteX software adds increased functionality to support the more advanced features available on the VerteX system, including power density control. On the analysis side, we have incorporated an advanced Fourier Transform based algorithm for thickness determination.

Continuity leads to another major benefit – there is no learning curve. An operator familiar with the existing RPM2000 will require minimal training to operate the VerteX system. Standard operating procedures will need only minimal modification.

Accucolor Software

Accucolor is a software application that enables the color of visible LEDs to be determined by mapping the Dominant Wavelength, ëdom, on an LED wafer prior to device processing. When combined with VerteX’s capability to accurately match PL to EL –Accucolor is a powerful predictive tool that can enable higher yields and reduced waste.